Replace your own inground pool liner, and save thousands of dollars over local installers! Installing your own inground pool liner is easy, when you take it step by step.

I will assume you have already measured your in-ground pool with our liner measuring forms, following the steps in a previous blog post written by Jackie on how to measure for an inground vinyl liner. Or if not, here’s some help:

Measuring your Pool

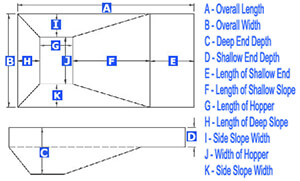

Accurate measurements are key to getting a liner that fits like a glove. Most inground vinyl pools have a geometric floor shape, with precise angles. The corners of the pool, at the top of the wall, have a specific radius measurement. And, most pools have square measures – with both ends and both sides being the exact same length.

However! Many pools are built just slightly askew, and end-up a few inches off from spec.To be sure that you order a correctly fitting liner, measure your pool correctly, and double check your measurements.

You may have measures available from a previous liner order, or you can probably dig up the original spec sheet which shows the length, width, depth and radius of the corners. However! Most pools will vary from the original specs, and can slightly shift over a period of many years, so it’s always recommended to remeasure the pool, completely.

You will need a measurement form for an inground pool liner. These are fairly standard, but it’s best to use the form provided by the dealer that you plan to order the liner from.

Measurement Equipment:

You will need a 50 ft measuring tape, rigid or flexible, and a 25 ft rigid tape. A pool pole is used as a vertical rod to measure distances across the floor. A clip board and pencil to write down the pool measurements.

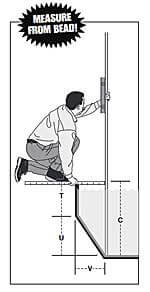

Measuring the Depth of the Shallow End

Use a rigid measuring tape, being careful to measure from the bead or track, to the flat floor. For the deep end depth (C), run a tight string (or flexible measuring tape) across the deep end, on the edge of the hopper and use a pool pole, or other long pole, placed into the corner of the hopper. Measure the pole at the point where it intersects the string, and then subtract the distance from the deck to the liner track, or bead. You can also use two pool poles at 90 deg angles to each other, to help hold the vertical pole in position, on larger pools. Holding the pole with a carpenter’s level as shown here, is not usually attainable, as (V) is normally at least 4 ft. wide.

Measuring the Length of the Pool

Tightly secure a flexible measuring tape (the reel-up type), the length of the pool, then use vertical pool poles to measure the length of each section. Your helper should eyeball the pole to make sure it looks vertical, and is not tilted. When measuring the slope from shallow to deep (F), do not measure down the slope, but measure horizontally to a pole held vertically. You can also use a plumb bob on a horizontal pole, and measure to the vertical string. Once you know 3 of the 4 measures, you can extrapolate the fourth, as long as (E+F+G+H = A).

Measuring the Width of the Pool

Use a pool pole held vertically in the corner of the hopper, and measure horizontally from the liner track to the pole. Do not measure down the side-slope, the measuring tape should be horizontal. Switch sides and measure the width of the opposite side wall. You can then extrapolate the width of the hopper, as long as (I+J+K = B). Typically, the K and I measures are the same, but don’t assume, they can be different.

Measuring Pitfalls to Avoid:

- When measuring F, H, I and K – don’t measure down the slope, measure horizontally to a vertical pole.

- When done measuring, check that A and B measurements add up to the total of all length and width measures.

- Check A and B measures at top of the wall and bottom of the wall, to be sure walls aren’t leaning.

- Measure depth from the flat floor, (not the top of any coved sand) – to the bottom of the liner bead track at top of wall.

- Keep your vertical measuring pole straight, or use a plumb bob on a horizontal pole.

None of the work below should be done before you have the liner and materials ready.

Choosing a Replacement Liner

One of the fun parts of putting in a new pool liner is choosing a new pattern or style. Darker colors will absorb slightly more solar energy. Tan and Grey tones have become popular lately, to blend with neutral backyard colors. Most patterns have a mottled pattern, to help hide dirt and mask wrinkles or imperfections. If you can afford it, I would always recommend choosing a thicker liner – 28 or 30 mil, rather than a standard 20 mil pool liner.

Warranty is another way that liner manufacturers differentiate their products, but keep in mind that a true warranty claim, for defects in materials or manufacture, is rare. 99% of liner failures are caused by pool chemistry or Acts of God. Also, most warranties are pro-rated, so a 25 year warranty may have little value over time. Liner warranties typically cover seam or bead separation, but won’t cover punctures, or sun or chemical deterioration. Specifically, inground liner warranties only cover you for “defects in materials or workmanship”.

When you order a pool liner, you may also consider ordering wall foam and adhesive. If your steel walls are rusty, or to just add a soft feel to your walls, 1/8″ thick wall foam is added to the walls before you install the new liner. There are several great liner manufacturers in the states, and lots of good vinyl comes from Canada – some well known liner companies are Pen-Fab, McEwen, Tara, GLI and Swimline.

Choose a pattern and style that you like, you’re going to be looking at it for many years!

Supplies needed to replace your inground vinyl liner:

- Custom vinyl inground pool liner

- Wall Foam and spray adhesive if desired or needed

- Floor repair sand or vermiculite

- 2 – 1″x12″ boards to stand on

- Duct tape

- New faceplates and gaskets for skimmer, returns, main drain, light

- 2-4 people for step #3

Tools needed for liner replacement:

- Razor Knife and Putty Knife

- Flat head Screwdrivers

- Liner Vac or HD Shop Vac

- Extension cord

- Push Broom

- Cordless Drill with #3 Phillips Tip

Getting ready to replace your inground vinyl liner:

When you get ready to begin, the first steps are to safely drain the pool to the storm drain or far from the pool, where it won’t flow back under the pool. Sanitizer level should be near zero, and the pH should be between 6 – 8, to protect your local watershed, but it need not be clean and clear.

Check the Weather

The weather does play an important part on the liner installation also. You want the temp to be at least in the 60s and a sunny day makes for an easier liner install. Check the weather, and avoid overcast or rainy days. On the flip side, being too hot can also be a problem. When the temp is in the high 90s and the sun is beating down on the liner it tends to stretch out and expand the liner, making it harder to get a wrinkle free liner installation.

Assemble the Team

A vinyl liner installation is easily done with two people, having a third or fourth person on the job is helpful, especially when you are pulling the liner across the pool, and locking the bead into the track. Planning your installation during spring break, or stretched out over several weekends, may help in obtaining helpers. Pay a decent wage, and you should have no trouble putting a small team together.

DRAIN THE POOL

If the pool has severe algae and large volumes of leaves and other debris, consider renting a small ‘Trash Pump’. Gas powered trash pumps can pass solids up to 1″ in size. To get every last drop of water, and drain the pool completely, remove the main drain cover and use a sponge and bucket. You can also use a cover pump, or a wet/dry vac or even old towels, to get up the last few gallons. Set aside the drain cover and screws for now.

Wait to drain the pool until you have everything ready to go, and a good weather forecast. Leaving your pool empty for very long could damage the pool walls or floor, if freak weather and floods move in before you have a chance to refill the pool.

A submersible pump can be set in the pool to drain it slowly, in 10-30 hours, depending on the pump size. Some inground pools can drain most of the water out of the pool from the main drains, using the filter pump. If you have a multiport valve, set it to waste, and run out a long discharge hose, away from the pool (and your neighbors!). Close the skimmer valve tightly and keep the pump running (and draining) until the main drains begin to suck air. The remaining water can be removed with a pool cover pump or small submersible pump.

You will need to drain ALL of the water out of the pool. Get the last bit with a mop and bucket, large sponge, a shop vac or your cover pump. Five or ten gallons spilled won’t hurt the floor of the pool, but don’t remove the floor of the liner with inches of water still left in the hopper.

Pool Draining Pitfalls to Avoid:

- Discharge the pool water too close to the pool, and it can weep into the pool, or put pressure on weak walls.

- Water should be balanced and low in sanitizer and algaecides, to protect the watershed. Green water is OK!

- 20,000+ gallons is a lot of water, be sure that you are not eroding or over saturating a hillside.

- Some areas have pool drainage and discharge restrictions and regulations. Check your local govt. website.

- Don’t flood a downhill neighbor’s garden, garage or basement!

- Check the weather, flood waters and high water tables can cause problems for an empty pool.

CUT OUT THE OLD LINER:

Cut the liner with a razor knife at the base of the wall – all the way around the pool, and under the pool step. Then cut vertically from the floor, up thru the top bead in several spots around the pool. Carefully pull the liner from the track by lifting up and outwards, the plastic track may be brittle and can crack if stressed. Roll-up the wall sections, and remove from the pool. Leave the floor section of vinyl liner in place for now, keeping it in the pool until you are ready to work on the floor.

Carefully remove, with a large #3 Philips screwdriver, the faceplates for the skimmer(s), wall return(s), main drains, pool lights, and pool step sections. You can use a cordless drill as well, but be sure to use a large #3 Phillips bit.

Safely store your screws, so not even one gets lost, we usually use Zip bags for the screws. The screws will not need replacement if they are not damaged. It is however recommended to replace the faceplates and gaskets, except for the step gasket, which is a very thick and durable rubber seal.

Order the correct gaskets (they differ by Manuf.), for your skimmer, main drain, pool light and wall returns. There are two gaskets used, one behind the liner, and one on top of the liner.

New faceplates for the skimmer, drain and returns are also recommended, as older plastic faceplates will warp and crack, which makes a poor seal that can seep and weep water.

Step 1: Wall Prep

Now that you can see the wall, inspect it closely for corrosion, rust or any odd stains. If there is anything that looks like rust or severe mold or mildew, you should scrape and paint these areas then follow-up by adding Wall Foam.

If you have holes through your wall, that’s more than Wall Foam will handle, you will need to patch with sheet metal or heavy plastic, then follow-up with Wall Foam. Wall foam can also be added just to improve the feel of the wall, which feels rather hard and cold without it. Wall foam is easily installed using an adhesive spray, using 2 or 3 cans per pool.

While inspecting your walls, you may decide to duct tape the wall joints, where the panels come together. This helps hide the seams, as seen through the liner. Any separation or suspected leakage can be filled in with silicone or other elastomeric sealant.

Inspect the liner track at the top of the wall, and clean it out with a hand brush or pool brush. If you have any areas that are cracked or broken, Super Glue makes a quick repair. For missing sections, ask your dealer for a section of liner track.

Inspect the surfaces of the wall where the faceplates attach – skimmer, returns, light and steps. If you see rust, this indicates that it has been leaking. Clean it up as well as you can, using rough sandpaper, steel brush or wire wheel. Paint it with a rust tolerant paint like Rust-O-leum or Krylon. After cleaning the surfaces, use small strips of duct tape to secure the skimmer, pool light and main drain gasket, the one that goes under the liner (there’s a second gasket used on top of the liner).

If You Have a Pool Light…

If you have an inground pool light, with a cord that runs through the wall, you will have to remove the light completely, to install a new liner. First, shut off power and open up the junction box. The J-box is usually off the deck, directly behind the light, or on older pools under the diving board. After removing the wire nuts, and loosening the clamps, duct tape a long piece of string to the wires. Pull the wire cord out into the pool, pulling until the string comes into the light niche. Cut the string with your razor knife and duct tape it to the inside of the niche.

Be sure to order new pool light gaskets, and possibly a new light ring as well, if it looks aged, yellowed or is cracked or warped. The SS screws can be reused as long as the Phillips heads are not worn smooth, aka stripped.

Step 2: Floor Prep

When you have completed the wall prep and you have checked the weather to be certain that you can continue from this point to completion, we can begin to remove the liner from the pool floor. Cut it with your razor knife into long strips, roll-up and remove in sections.

Concrete or Vermiculite Floors:

Sweep the floor clean with a broom and/or leaf blower. Use a dust pan, or wet/dry vac to remove all of the little pebbles, grit and granules. Fill in any holes with a Concrete/Sand mix, a Vermiculite/Concrete mix or just plain Vermiculite mixed with water. Clean the pool deck areas around the pool, and/or wet them down, to prevent debris from blowing into the pool.

Sweep the floor clean with a broom and/or leaf blower. Use a dust pan, or wet/dry vac to remove all of the little pebbles, grit and granules. Fill in any holes with a Concrete/Sand mix, a Vermiculite/Concrete mix or just plain Vermiculite mixed with water. Clean the pool deck areas around the pool, and/or wet them down, to prevent debris from blowing into the pool.

Sand Bottom Pools:

Sand floors require much more work to prep, and you have to work and walk very carefully around the pool. You’ll need large plaster trowels; the stainless steel, rounded end type. Remove any spoiled or odd-colored sand and replace with new. Remove any small pebbles or windblown debris. Low areas can be filled in new sand, but be careful not to add too much sand, or you will raise the floor higher, this could make the new pool liner fit poorly.Trowel the floor smooth, starting in the deep end and working your way out the shallow end.

Use the 1″x12″ boards to move around, these dig into the sand less than your shoes. Large 2×4’s can be used to roughly screed flat areas, finishing with the trowel. Lower raised areas by pounding them down or scraping off high spots, and fill in the low spots. It needn’t be absolutely perfect, as most patterned liners will hide minor floor imperfections, but try to get it as level and even as you can.

Pay particular attention to where the wall meets the floor. If this area is wavy, and not fairly level, it can look odd. Around the deep end of the pool, you can choose to trowel in place, a safety ledge of 4-6″ where the wall meets the floor.

As you go, measure carefully from the track to the floor, all around the pool, to be sure that the pool depth will match the ordered liner wall height, consistently around the pool. Wrinkles or uneven stretching will result if the floor height (or depth) is not equal all around the edges and across the floor.

Prep Work Pitfalls to Avoid:

- Be cautious working around an empty pool. Falling into empty pools can be hazardous!

- Be Prepared for the Prep Work, so you can finish wall and floor prep as fast as possible.

- Once the floor is ready – install the liner quickly before debris blows into the empty pool.

- Darker swirl patterns will hide wall and floor imperfections more than light blue liners.

Step 3: Install New Liner

Give the floor of the pool one last inspection for anything that might have blown in the pool. Clean off the pool deck if needed, to keep the pool clean. Remove the main drain faceplate, and replace the gasket, taping it in place so the holes line up, and so it won’t shift while under the liner. Be careful to keep sand out of the main drain ring and cover screw holes.

Wall is prepped, floor is prepped, and we can now open the new pool liner box and follow the included instructions. Look for the tags that indicate deep end or shallow end, and orient the liner as you prepare to pull it carefully across the pool.

With at least 3 people, one to hold the shallow end wall, two others will grab opposite sides of the liner and pull it across the pool to the deep end wall. Bend down and lock the corners into the tracks. Pennies or Popsicle sticks can be useful as a shim to hold the liner in place as you move it around to line it up to the pool corners.

Once the corners or other markers are established, and the liner appears to be hanging correctly, proceed around the pool, away from each other and lock the liner into the track. Pull any slack along the wall with you, as you go, keeping a slight tension. It is not uncommon to need to shift the liner a few inches, if it ends up slightly out of alignment. Take your time and go slowly through these next few steps.

Pull Up the Slack:

Lay down on the pool deck next to the pool step section, and lean way over the edge to grab the vinyl on the floor. Your helper can do the same on the opposite side of the steps. The purpose is to grab the liner off of the shallow end floor, and pull it towards the shallow end wall, to take up the natural slack that the liner will have towards the deep end. You can place sandbags or Water Bags up against the shallow end wall or under the step section, if it seems that you need it to help prevent the liner from slipping toward the deep end.

Lock in the Bead:

Two people work in opposite directions, locking the liner bead into the track. Start in the shallow end center, and pull opposite each other, to remove small amounts of slack, while keeping the corners in place. If you have a step section in the shallow end, you can use some duct tape for now, to help hold the liner over the span of the steps. Continue all the way around the pool, locking the liner snugly into the track. Do this from outside the pool, leaning over the edge. If the liner fit is either too tight or too loose in the track, you can use strips of Liner Lock, a rubber wedge that you push-in between the liner and the track.

How’s it Hanging?

After it’s all in place, take a look to check the “hang” of the liner. The corners should all be central to the actual corners, although they will be very slack. The wall material should hang straight down, and although loose and wrinkly, any folds should be running vertically. If they run diagonally, you may need to shift the liner in the track somewhat. The vinyl covering the floor should also lay flat, and lift off the floor at the sides, where it meets the wall. Floor wrinkles can be pulled out by leaning over the pool edge and pulling on the liner, or using a push broom or pool brush to push them towards the wall.

If you have a step section, lay a 2×4 across the front of the steps and duct tape the liner to it, at the same height at the track. Small sandbags or water bags laid under the bottom step, on the liner, is helpful to simulate the weight of the water. When the liner is positioned properly, install the 3 strips around the front of the steps, bottom and both sides. Tighten down the screws very tightly against the rubber gasket. After all screws are tight, cut out the section of vinyl – and walk out of the pool!

Liner Installation Pitfalls to Avoid:

- No smoking around the new liner!

- No sharp instruments, No shoes.

- Install during 65-85° F. If cold, keep the liner inside a warm house until ready.

- Don’t install any faceplates until the pool is full of water (except main drain).

- Plan your installation, to order all gaskets and faceplates ahead of time.

Step 4: Set the Liner

Next step is to hook up your Cyclone Blower Vac to set the liner. You can also use a large, heavy duty shop-vac of at least 5 hp to set the liner.

Set up the vac on the edge of the pool, in the middle of a long side. Connect a 4-6′ hose to the suction port of the blower/vac, and run the hose behind the liner, by pulling a small section of liner bead out of the track. Push it down behind the liner a few feet, about a foot above the floor.

Use duct tape to seal up where the hose goes behind the liner, and to seal up the skimmer lid or a pool light cord. If all air leaks are sealed, in under a minute the Cyclone will pull the liner tight against the walls and floor. Make sure all valves on the filter system are closed to prevent sucking air through the pipes.

If you have a main drain, you will need to install the faceplate ring and the lid at this point, after the liner is set. Carefully walk down to the deep end, using boards if you have a sand bottom. Locate the screw holes under the liner, and install the ring and new gasket. Screw down very tightly with a #3 Phillips screwdriver. Then install the main drain cover securely.

If there are wrinkles in the liner, turn the vac off and work the vinyl, trying to pull the wrinkles toward one wall or the other. Banging the lower wall with a push broom, or gently persuading wrinkles with the the wood edge of a push broom, works well. Turn the vac back on and you should have most wrinkles removed.

Step Sections:

There are several ways to seal up the step. In some cases you can just use a lot of duct tape, but for larger steps, you’ll need to lay something flat across the top of the steps, and duct tape that to the deck and to the liner, to be able to achieve a full seal. A large flat sign, or cardboard sheet can be used. Some people cut a large section from the old liner and lay that across the steps, taping or weighting it down. Lumber can also be used, such as several 1×12″ boards laid across the top. You may ask “why not just put on the step tracks and screws?” That is done later, after the liner has stretched into place. Don’t make any holes for the step section, until the water level is up to the bottom step.

When you seal up all of the air leaks, you will see the liner magically suck itself tight in just a few minutes. And now you can really see how the liner fits, how it meets the corners – and if there are any wrinkles.

Wrinkles:

Don’t freak out if you see a few wrinkles, it’s normal. Most pools have a few at first, it just takes some finesse to work them out, by pushing and pulling them towards the wall, or expanding them across the floor. Try to do the work from up above if you have a sand floor, or use two 2’x3′ boards to gently move around the floor. Even with vermiculite or concrete floors, try not to enter the pool, and if you must, walk very gently.

To work out wrinkles in a liner, you can use your hands to “massage” or spread out the wrinkle. Try laying on the deck and leaning way over the edge, grabbing a handful of vinyl (you may have to shut off the vacuum temporarily), and pulling towards the wall, and releasing the liner slowly into place. You could also use a push broom or pool brush on a pole, to gently push the vinyl in directions away from the angle of the fold, or wrinkle. Sand bags or water bags can also be used to hold wrinkles back until the pool fills.

In some cases, you may need to unset and reset the pool liner several times before you get it set without wrinkles. In some cases, you have to move on, and work on them later, as the last few wrinkles may be more easily worked out when there is a few inches of water covering the area.

Pool Liner Setting Pitfalls to Avoid:

If the liner does not suck tight in 5 minutes, find the air leak and try again.

If the liner does not suck tight in 5 minutes, find the air leak and try again.- Large pools, or L-shapes may need two vacuums running before the liner will set fully.

- Some wet/dry vacs aren’t strong enough for the job.

- Use 20 amp circuits (Kitchen/Garage), with HD ext. cord, to not trip the breaker.

- Vacuum must run non-stop until pool is half-full of water, or 3″-6″ deep in shallow end.

Step 5: Fill the Pool

At this point, there are usually high-fives and maybe the sound of beer cans opening. The vac must stay running until the water level is about 6″ above the floor, or just beginning to cover the hose. Continue to fill as you remove the vacuum hose and duct tape and pop this area into the liner bead track. Most average size pools will fill from the hose(s) in 36-72 hours.

With just a few inches of water in the hopper bottom, carefully walk down to the deep end and put on the main drain faceplate ring, top gasket and main drain cover. There is already one gasket under the liner, now place a second drain gasket on top of the liner and then screw on the main drain ring, or faceplate. Be sure to tighten down the screws very tight, until you hear the plastic begin to creak. Then, use a razor knife to cut out the vinyl circle inside of the ring, and then install your main drain cover, with two stainless steel screws.

Wrinkles: Monitor the pool for wrinkles as it fills, or check the small ones that you saw earlier, to be sure they are stretched out. Some wrinkles just naturally flatten when a few inches of water is on top of them, and the weight of a few inches of water can be helpful in smoothing out wrinkles in the floor, by pushing them toward the wall, or spreading them out. If there is too much water on top of a wrinkle, say more than a foot, it can be harder to pull them out. If you have a sand bottom, you can sometimes push wrinkles in, to the floor, if they are very small folds.

Pool Filling Pitfalls to Avoid:

- No tripped breakers! Plug into a strong 20 amp outlet, keep the vac plug dry if raining.

- Wait to install step, light, skimmer and return faceplates until water level is up to them.

- Don’t fill over your vac hose, it can be hard to remove when under water.

- Corded electric drills can be hazardous around pool water (cordless is ok).

- Install the main drain gasket, ring and cover when 3-6″ has filled the deep end.

Step 6: Cut-in Steps, Returns, and Skimmers

We don’t install these until the pool is full, because the liner is still stretching into place. When the pool is full, install the faceplates and gaskets very tightly – with a proper size screwdriver. To prevent any leaks make sure the gaskets are solid and the screws are tight. When the plate is re-installed, cut out the vinyl inside the faceplate and flood the lines with water.

If you have a pool light, now is the time to install the ring and new gasket, and reinstall the light fixture into the niche. Reconnect the cord to the string securely, and pull the cord back through the conduit to the J-box. You may be able to reach it from above, hanging upside down, or standing in the deep end reaching up. If you need to stand on something, make sure it’s soft, or placed on a broad, flat surface, so that you don’t damage the new liner.

Steps & Seats

When the water level reaches the point where it’s almost reached the first step, or bottom step, it’s time to screw on the step strips, the 3 long plates and about 50 screws, that gaskets the liner around the steps. If the liner looks loose or is wrinkled, pull up on it, or push out on it. If necessary, use small sand bags to help hold the liner up against the wall, under the step.

Gaskets: Most step sections have a heavy duty rubber step gasket that holds up to many liner changes. If you noticed rust around the step strips, inspect the gasket and replace the heavy rubber gasket if necessary.

To install the step strips, start with the bottom strip, and with a cordless drill, screw all of the bottom strip screws in place, starting in the center and working your way to the outside. Then you can install the side strips, working from the bottom towards the top. Once all 3 step strips are screwed on, go over each one again to make sure they are double-tight. Then, trim out the vinyl carefully and close to the edge of the step strip. Install the screw hider strips and you’re done!

Steps and Seats Pitfalls to Avoid

- Without water in the pool, be gentle on the step section, it could crack.

- Clean the step gasket, or use the step gasket kit if it looks damaged.

- Don’t use an electric drill, if you drop it in the pool, you could die!

- Don’t pull up on the liner as you make your initial screw holes, leave a little slack.

- Wait until the water is up to the screw holes before screwing in the bottom step strip.

Face Plates

The face plates for your skimmer and return should be replaced if they have some age to them. Returns have a permanent rubber gasket, like a step section, but also use a gasket on top of the liner. Buy your skimmer gaskets and main drain gaskets in pairs, once goes under the liner, and one gasket on top of the liner.

Screw on your faceplate screws very tightly, with the large Phillips (#3) head. Crank them down until you hear the plastic squeak and creak. Now you can cut out the vinyl inside the faceplate, trimming it close to the edge with a razor knife.

Pool lights also have a large light gasket beneath the ring, and usually a second gasket beneath the vinyl. It would be wise to replace these gaskets when you replace your liner. Vinyl pool light niche gaskets are found in the category of light niche parts. When the water level is up to the bottom of the light, have someone with long arms lean way over the edge of the pool and screw on the large light niche ring and gasket. Then cut out the vinyl inside the ring. Float the pool light across the pool, and hook/duct tape your string/wire to the pool light cord. At the pool light junction box, pull up on the string/wire to pull the pool light cord back into the conduit, and into the j-box, where the power can be reconnected and turned on again. Leave 3-4 feet of cord coiled up inside the light niche, to be able to pull the light out for future repair.

Faceplate Pitfalls to Avoid

- Make sure your replacement gaskets and faceplates are exact match before liner day.

- You need all of the screws – if missing one, find a factory replacement fast.

- Don’t use incorrect screws, or non-stainless steel screws. Only Skimmer Screws.

- Don’t use an electric drill, use a #3 Phillips screwdriver, or #3 tip on a cordless drill.

- Leave enough cord behind the pool light to pull it up on deck for service.

- Don’t poke any screw holes until the water level is up to the bottom of the faceplate.

- Don’t cut out the vinyl inside until the faceplate or ring is installed.

Now you can start the filter system, balance the water chemistry and enjoy your new inground pool liner. Installing an inground vinyl liner is not too difficult, especially if you’ve measured correctly.

I purchased a semi-in-ground pool which will be buried half in-ground. I plan to install this fall but was thinking of installing the walls for now and wait to install the liner in the spring. What are your thoughts? Zone 6 (Toronto)

Hi Michael, yes I would be alright with that, however I think I would delay most of the backfilling up against the walls, until spring, but yes you can excavate for the pool and trenches, install the walls, install plumbing and electric and the filter system, so then in spring you just have to finish the floor, backfill and tamp and install the liner, then landscaping and walking surfaces around the pool.

Hi, we got a new liner installed yesterday and we turned off the two air vacuum units before it reached out the level of water in the shallow end as it was getting too late last night to complete the process. Can we start the vacs and the water back on to continue filling the pool.

Yes, turn the vacs back on, and look closely for any wrinkles that may need persuasion, or pushing towards the walls, as you fill. Liner vacs should be left on until water reaches the shallow end, hopefully you don’t have any big problems with wrinkles or a liner that slipped towards the deep end.

You can also disassemble light and tape light shell inside of light opening. Hang liner and install gasket/sealing ring. Cut out liner inside of ring and pull light shell up to deck and reassemble. Easy peasy

is there such a thing as an inground pool liner made of kevlar. if not what is the next most durable liner.

Hi William, that would be something, however there is only vinyl available for pool liners. The most durable would be the thicker liners, of 25-ga or 30-ga thickness. Standard thickess is 20-ga.

I need to install new step pad and new steps. Do I need to drain my pool to do this?

Hi Duane, no not at all, above ground pool steps are installed with water in the pool

how to install new stair seal does it go on outside or in ? do you glue it to keep it in place ?

Hi Greg, you do not need glue. The gasket goes under the liner, and the plate goes on top of the liner. Be sure to crank those screws down very tightly, using a #3 Phillips.

I am trying to replace my liner but i have a high water table and can not stop the water even with hydro cement. I have two pipes one on each side of the deep end i have been told they are dry wells. Can i pump them out to stop water from going in the pool?

Hi Jon, sounds like what those are used for, a dry well that you can connect a pump to, probably had the same problem when building the pool. So you just need to buy or rent a thin submersible pump of 1.5 hp or so, something substantial, not a cheap little pool cover pump, but a real ‘sump pump’- connect a discharge hose or pipe, and lower it into the dry well, and then plug it in. This is discussed as Option 3, in this blog post Inground Pool Construction and Groundwater Issues

Dan, I have a lagoon style pool that is 5ft deep everywhere. Everything I read says the take the new liner to the deep end with the arrow facing the shallow end to start installation. But I have no deep end,so how do I know how to line up the liner correctly, because on a lagoon style pool the walls curve in and out, and I see nothing on the new liner that shows what goes where. Thank you.

Hi, in that case, you will want to pull the liner across the pool, with 2 or 3 helpers, and flip it around if you need to. If you have any corners at all, you can use it as a starting point…

I need to re-trowel just the deep end of my pool as water got behind it and caused the sand to slide under the liner. Is it possible to do this without installing a new liner? Thank you!

Hi Fran, maybe – probably. But only if the liner is young, and still pliable enough. If the liner is brittle, faded and old, it may ‘snap’ or break when trying to reset the liner with a vacuum. Also an old liner may develop wrinkles when re-set, or perhaps not fit as well. Older liners shrink somewhat when water is removed. So, if the liner is old and faded – get a new liner first. If the liner is in OK shape – then go for it, pulling the liner out of the way, re-trowel the floor, and then re-set the liner with a strong vacuum. You may also want to do some work on the path of water around the pool, to avoid a similar situation, if caused from a high water table. Good Luck – I’ve had similar situations I’ve worked with before… PS – while the pool is drained, you could measure the pool for a new liner, just in case you need it (now or later)- and because it’s more accurate to measure when empty.

Davy: I fill my spa from well water so I always use a “metal-be-gone” type of product when I start. I use bromine. It seems like a long time and lots of bromine tabs and shock to eventually get a stable level. I do use the bromide starter. If I use too much of the metal protector, does this bind up the bromine? And does it bind up calcium too? thanks

Hi Scott, the Stain & Scale product does bind up the calcium, but not the bromine. I would suggest using a double-dose of bromide starter next time you drain and refill.

We just had a new liner installed on our inground pool. We noticed that the liner is not tucked in the track. You can see where the liner ends. And in the corners you can see a bigger gap where the liner is pulling away. Is this normal or should the liner be in the track and not already pulling away on the corners?

Hi Tracy, not normal, but not uncommon. I would call the company out and have them use liner lock to secure the liner back into the track – important to keep water out and stop it from coming out of the track more. They may need to lower the water level a foot or two, to be able to get enough stretch, to pull the liner back into the track, and may use some heat on the vinyl, for the same reason. Then once it is locked into the track, the Liner Lock product is used.

What is the the metal part that goes around the rim of the top of the pool called.it is secured to the concrete. It has white clips in specific increments around it. New this pool thing thanks

Hi, for inground vinyl pools, that sounds like the coping you are referring to. Very difficult to remove and replace, but it can be patched with epoxy putty, or painted. The clips are just to hide the area where the sections are joined. Not widely available if you need to buy, but can be found at pool distributors, and a few websites carry “inground vinyl pool coping”

I am installing new step mouldings w/ new liner: Looks like I install the mouldings to the steps first after liner is in position & salt bages against liner to hold in position. Now do I cut the new mouldings on a 45 angle @ the bottom corners and round them off, or just but the side mouldings to the top of the bottom one ?- I have end caps if butted.

Hi Bruce, normally I see them cut at an angle to meet, like a picture frame, with 45 deg corners – but yes, with rounded edges, so as not to poke at the liner. I suppose you could also but them up against each other, probably would work fine also. I normally wait to install the step gasket and trim kit until the water level is up to just beneath the bottom (horiz) trim piece, but you can approximate by setting the liner with a vacuum and using sand bags, however the water may still stretch the liner, and stretch the screw holes, until they open up into big leaking holes (like happened to me once, arggh)

I just installed a new liner but there appears to be a small pebble on the pool floor that didn’t get vacuumed prior to install. How do I get it out?

Hi, been there before! If the floor is a sand bottom, you may just try to work the pebble into the floor. If not, well there is no way to get it out except for … getting it out. Otherwise just ignore it, and it may cause no problems. the worst that could happen is that it wears a hole in the liner after several years of the water weight, or pool cleaner running over it, then you can pull it thru the vinyl and apply a small vinyl patch over the hole.

Can I leave the amerlite pool light in the stainless steel housing and pull it out just prior or after to installing the liner light ring? I have 80′ wire to the switch so this would work best if you agree.

I have an 18′ x 36″ rectangle with an 8′ deep end hopper where is the best place to insert the vacuum nozzle (I have two skimmers one in the deep and one in the shallow end. I seen in a video to tape cardboard over one of the skimmers and insert the hose there do you recommend that practice?

Hi John, the light will have to come out before you install the liner. After the light ring is installed, when the pool is nearly full of water, then you cut out the vinyl inside the light ring and can install the light. Attach a string to the end of the light cord at the J-box, and leave the string inside the light niche, to help pull the light cord back through the conduit to the J-box. For the vacuum hose, I usually use a mid point of a long wall, somewhere equidistant to all points. I don’t usually use the skimmer, but just pull open a second of the liner (about 6″) and pop the hose in, then seal it up with duct tape. But this skimmer method is valid too, then there’s no worries about the liner stretching around the hose, or the hose getting stuck behind the liner.

Have 20 x 40 x 8 final liner was replaced in 2017 cover taken off this year wrinkles all over shallow end what to do now

Hi Mike, sorry to hear… many wrinkles can be flattened-out if you have a sand floor, or moved toward the wall, slowly with the water level lowered to just a few inches over the wrinkle. You canalso drain below the wrinkles and use a vacuum to reset the liner while refilling. Wrinkles can develop a memory, so it’s best to tackle it asap. Probably was caused by water getting under the liner, which could be another thing to fix – drainage of water around the pool.

My 12×24 pool was installed June 2018 with 12ft stairs. A month after, a wrinkle was discovered in the deep end floor about 6″ up from the bottom. How can I find the cause of the wrinkle by process of elimination? The wrinkle grew to about 4ft by the end of August 2018.

Hi Irene, a wrinkle as you describe sounds like the vinyl relax, and pulled away from the shallow end, and sort of slid down the slope towards the deep end. You may notice the vinyl pulled away slightly from where the bottom step meets the floor, in the shallow end, or maybe not. The liner could be a bit too large for the pool, or you haven’t noticed any water pooling under the liner, have you? It may be possible to work the wrinkle into the deep end hopper, spreading out the wrinkle at the junction of the slope and the hopper pad in the deep end. Good luck!

I have a question. About 4 or 5 year ago my liner developed a bad leak. I tried patching it and kept losing water. I gave up. It was going into winter time. During the winter it totally empty out and then I ran into money problems. I still don’t have the money to have it installed however I could probably do it myself. The cover ripped cause no water and the liner is in pieces. Is there anything besides what you mentioned to do to get it back into shape.

Hi David, was the pool winterized properly? To rule out any issues with the plumbing or filter equipment. I would also check the walls and floor, to be sure there is no bowing or damage to either of those. Remove the cover, cut up the liner and inspect the pool really well, and if it all looks normal, then yes it is just the 5-steps mentioned here to replace your inground liner.

Dave, I recently had a new liner installed installed in my sand bottom in-ground pool with bottom drain. The installer did little if any troweling and failed to use boards to walk on. The result is huge amounts of large dents, divots, and crevices on the slopes and floor. Some are as large as half baseballs and golf balls and there are complete shoe and bare feet marks all up and down both sides of the slope. Where the sides meet the bottom the lines are wavy and uneven. I had the owner of the pool company out and he agrees that his crew did not do the job right. He proposes to drop the water level to a foot or so from the bottom and try to smooth out the imperfections without removing the liner. My question is: will this procedure work adequately or will it be a waste of time and water?

Hi Glenn – it will work well on some areas, but for divots the size of a half-baseball…? Not sure, but in the manner he suggested, sand can be moved around and smoothed out effectively – I like to use a 4′ piece of 2″ PVC pipe, with a 2″ Tee fitting on the end. If he thinks he can get it near-perfectly smooth, go for it – but let him know that you expect it to be near-perfect, or you will ask for the liner to be removed and reset, after proper floor troweling.

Hello

Just had a replacement liner installed ( by pool company) in 40×20 Inground pool now filled with water. Around the bottom perimeter of the shallow end the Liner is not sealed snug into the 90 deg corner (at floor to wall intersection). There is essentially a 1 to 2 inch radius with no support behind the liner. I am concerned that the liner will be easily damaged around the bottom perimeter of the shallow end. We are concerned that pool vacuum (Kreepy Krawly) will damage the liner in the unsupported corner radius. The corners around the bottom perimeter of the deep end (including the slope down to deep end) appear snug and supported. Would appreciate your opinion on the condition described in shallow end and our concerns. Thank you.

Hi Cal, thanks for the excellent description of the problem, I understand. You are correct that such areas not tight against a wall or floor, but suspended between, are more vulnerable to punctures. I don’t think the kreepy will harm it however, being so slow and soft, as long as it doesn’t get stuck in the corner and suck at it for hours. Most likely this issue will not cause you any problems, I’ve seen it many times on many vinyl pools, without much consequence, so I think you can rest easy. Not an ideal installation, but sometimes it happens out there…

Within the past few days we’ve had a new liner installed in our unground pool which has rounded metal coping along the edge. We have not used the pool yet due to their being a few spots where the liner is out of track, also we’re scared because in the corners of the pool it feels loose (there’s give similar to pushing on a balloon not loose meaning it moves side to side).

2-part question, is the corners safe to be that way or should they be tight against the wall same as the sides of the pool?

Are they responsible on returning the liner?

Hi Tyler, it is common for a liner to be not flat against the wall in the corners, depending on the radius. Where the liner has popped out of the track, that means that the measurement is not exact, which it rarely is, but better too loose than too tight. The fix is to use Liner Lock, used as a shim to take up space in the track, and hold the liner bead secure.

Thank you, we were concerned about the corners having to much play. But should they leave us with a tool to push the liner in?

Actually, they should come back and do it for you, if the liner was just installed, unless it’s just a small spot that you can handle. There is no specific tool to push the liner back in track, just pull it up, fold it over and stuff it in there. You can a dull flathead, or a rounded handle of something to help if needed.

Hello, what would you suggest or recommend to resecure a vinyl liner back into the track? Currently,the liner is is hanging downward from the top edge of the pool (2 to 5 inches.) The length of the liner that needs to be resecured is 10 feet in length.

Hi Dennis, lower the water level about a foot, then use a hair dryer to heat up the vinyl, in small areas, starting at one end. Be careful not to melt the liner (which I did once!) with the hot air. AND – be extra careful not to drop the hair dryer into the water, which will electrify the pool (!). Work it slowly from one end to the other, heating up small sections and pulling up into the track (hard work for the fingers!). Then use Liner Lock, to use as a shim, above the liner bead, to take up space in the track, and help hold it there.

Should I put wall foam on the bottom of my in ground pool? I am worried about putting it on the slope to the deep end.

Tim, no I would not put wall foam on the floor, it can bunch up and create bumps under the liner. And, the joints where the sections come together will be visible under the liner, and create either ridges or valleys, both not attractive and traps dirt.

We had an inground pool liner installed by a pool company not even a year ago. Our old one was shrinking, faded, and popped out of the track in specific spots. Now after getting a new liner installed by the same company that put the Pool in when the hous was built in 2008, we are still losing water. The company people came out numerous times checking skimmers, light, etc. but could not find where it was leaking. At that point, we were at the end of swimming season and The company owner said we might just have to call leak detection people because he could not find the leak,however his son said upon opening he would recheck the light housing and do a pressure check on the piping. When we opened, he puttied a crack in the houseing in hopes we had finally found our problem. Nope!!! Still losing water. Now upon swimming I found where the liner is pulling in several spots beneath the steps. In fact, someone has put a patch on one of the pullings already which I never saw until I started swimming playing with my kids. I called the Pool company and they do not know why the not even a year old liner is pulling already and suggest that might be where the water is going. I’m waiting on their arrival to look at it again, but wondering what to or why this is happing to us as far as the liner goes.

Sondra, if the step screws were installed before the liner had fully stretched, a leak can occur, around the screws running horizontal, below the bottom step. If you see a patch in this area, that is likely what happened – which would be entirely their fault and responsibility. The screws should not be put into the steps, until the water level has reached the bottom step, or first step, so that the liner is already stretched, before the screws are put in place.

When do I install the bead lock cord?

Hi Alanah, Liner Lock is installed after a (beaded) liner has been installed, to take up space between the liner bead and the track. It is not always needed, only if the liner is either a bit too short, or too long in the wall measurement, which can cause the liner to come loose from the track. Liner Lock is a “SHIM” for loose or tight liner beads…

I do understand what it is. My question is at what point do I install it. Before or after filling with water. I purchased a new liner through In the Swim. Installing now.

Hi Alanah, install Liner Lock after the pool is full of water.

should the seams in the liner be fitted where the walls and the floor meet. Because my liner seams are about 2 to 3 inches from the wall on the surface of the floor. Is this going to become a problem in the future. any help would appreciated

Hi Artie, that is the general idea, the seam between wall and floor is usually on the floor, but right at the base of the wall. 2 or 3 inches from the wall, that could be considered normal – I would not expect any trouble in this regard, unless you notice any wrinkles on the floor also…

Hello iam installing my new liner this year , i know you replace the main drain and skimmer gasket under the liner and top . Do I need to do the same with the return or just under the liner ?

Hi Mike, good question. The wall returns usually have a rubber gasket that is used under the liner, and it usually is affixed to the fitting itself, so no additional gasket is needed, just the one on top of the liner.

It might be advisable to tell people to install the vac hose into the skimmer with a plate made from plywood to fit where the skimmer cover is removed, and a hole for the hose to fit snugly. tape up the plate around the edges with lots of duct tape, and plug the skimmer line (below the basket, or at the pump) to block air draw. That way the liner is always in the bead lock all the way around, through the entire process.

I’ve just had a quote to replace an inground liner which includes, the installers to lift the pavers, dig out the paving base & pool backfill to access the plumbing to the skimmer & inlets etc. Apparently this is required to cut out the pipe holes in the liner. Is this necessary? I haven’t read anything like this in your “steps to replace a liner”.

Hi Claire, no that is not required normally to replace an inground liner. There would be no need to access the plumbing on the back side of the pool wall, unless you NEED to change the wall fittings, due to leaking (behind the wall), but that is rare, and probably not indicated in your case. In 99.9% of liner installs, you just clean-up the wall fitting or skimmer sealing face (on the pool side), and replace the gaskets, one under the liner and one on top of the liner, under the faceplate, which should also be replaced. Same thing with the main drain, and any thru-wall pool lights. In-pool Step gaskets are heavy rubber and are often not replaced, unless excessive deterioration is found.

I had a new liner installed by a pool company. Within one month the liner was coming out of the coping. They came and fixed it and then it came out again within another month and they came and fixed it. I then had to close the pool for the winter and it turned into a year and 10 months before I could open it again. I had a mess cover over it. When I opened it again, the liner had come down in 4 places and it was down about a foot in two places. They came and tried to pull it up but said it was my fault for not opening it and having the chemicals and PH at the right level. The liner wasn’t down everywhere in the pool only in the area where I had trouble within a month of them installing it. Is that normal if the liner was installed properly the first time?

Hi Vivien, when a liner pops out of the track, it’s because it’s a bit too small, or a bit too tall – for the actual pool depths. in the area of the trouble, the liner is probably not as deep as the pool actually is, or the shape of the floor, or actual depth changed after the liner was measured. So, my opinion is that the liner does not fit the pool, and that is the reason for the liner popping out of the track, and because it’s too small, (not as tall as the wall), it drops down very low, and at a foot below the track, it’s almost impossible to pull up again, without draining most of the water.

I’m in the process of installing a new liner in an Inground pool, I need to remove a section of liner from the track to reposition it. Unfortunately I am unable to simply slide the liner along due to a seam in the track. I’ve tried pulling the liner out of the track but have had no luck, I’ve applied heat (carefully) but I am afraid of damaging the liner. What’s the best way to remove it?

Hi Joel, can you modify the uneven track area, with a file or rasp? This is where two sections of track join, right? If you can shave off the hooked edge, and then sliding should be easy.

Worked like a charm! Thank you! My next problem is getting the last section of liner stretched enough without other sections popping out. I’m pretty confident that the position of the liner is correct. It’s a kidney bean shape inground pool I’ve made several attempts each time starting at a different point and have had no luck, I’ve checked the perimeter measurement of the pool and verified the liner is correct any advice would be appreciated thanks again!

Kidney? Ahh, not easy to install. because there’s no corners to line up. Here’s what to do. Line up the floor seams, and apex of the curve on one side of the pool, then start to lock the bead into the track with two people, pulling opposite each other. every 5 feet or so, use pennies and popsicle sticks – to shim the liner, or you can also use duct tape, to hold the liner in the track, slightly stretched and TAUT in the track – before you move another five feet apart from each other and do the same thing. Keep moving opposite each other, 5 ft at a time, until you meet up again at the other side of the pool. Keep pulling against each other all the way around the pool, and you should end up with enough slack to meet at the end. You may need to adjust the liner laying on the floor as you get to the other side – I mean, you may have to pull the floor material evenly so that the floor material is laying flat, or is also pulled across the pool, and usually suspended over the deep end floor. A 3rd person is also helpful at this stage. Good Luck!

We have an 18×36 inground pool that is 8ft deep. It is rectangle with steps centered on one of the sides. It will need a new liner soon due to two of the corners having wide tears above the water line. Is this a project that my wife and I could do ourselves?

Hi Justin, sure! We sell thousands of inground liners every year, to DIY homeowners. Most of the work can be done with 2 people. The moment of installing the new liner in the track is easier with 3 people or even 4. The entire thing can be done in one weekend, without special tools. A liner setting vacuum is best, (like the Cyclone), but you can also use 5 hp shop vac, to ‘set the liner’, or suck it against the wall just before filling (and until half-full of water). The steps are the trickiest part, you may need a few sand bags to help hold the liner up against the bottom of the step, and lots of duct tape or other means to seal-up the step, so it doesn’t leak air, when you set the liner with a vacuum. And it’s a lot of screws to install (after the water level reaches the bottom step), but if you have a cordless drill, it goes fast. Any other questions or concerns, reply back! You can do it! 🙂

If I purchase a liner from intheswim, who can I find locally to install it for me? I have gotten quotes from 2 local groups and they will only install their own liner..

Hi Tim, great question. And yes I understand, most pool builders also want to sell the liner, and measure the liner etc. Some pool service companies will work with you, but many may not wish to – sometimes pool service technicians may do it as a ‘side job’ on a Sunday, if you ask them in the right way, I suppose. Or you can try calling a few Handyman services, they may take on such jobs. If saving $1500-$2500 appeals to you, you could do it yourself. We could even turn it into another inground vinyl liner installation blog post, with my help outlining the process in detail for you, in exchange for some photos of the process. But I’m glad to help either way.

I just had a new liner installed in my inground pool. After the installers left and the pool was filling I noticed a small 2-3 inch lion lump in the bottom of the pool. After feeling the lump it was obvious they installed the cover over a frog! Do you foresee this causing a problem in the future? I’m worried the bones may puncture the liner.

OMG… and geez. Maybe he jumped in at the last minute? I assume that he is pretty flat now, and will get … flatter. Probably won’t cause a problem, but possibly could. Frog bones are not very hard or sharp (I think), unusual question, and of course I have no direct experience with such a problem. Fingers crossed! I think you’ll be OK…

Hello, When the liner is replaced and the pool filled with water I thought you had to wait 3 days before adding chemicals and starting the filter pomp, is this correct?

Hi – no not at all, I can’t think of any reason why you should wait to add chemicals or start the filter…

Do you have to use a shop vac? Can be the water not just press the liner in?

Hi Cindy, in most cases, a liner vac is necessary, to prevent wrinkles in the floor of the liner. Larger pools may need two vacuums running to suction the liner tightly. However, there are those cases where in some small and shallow pools, with no deep end, if the liner is an exact fit, it could be done without a vacuum I suppose, but I’d like to see how it fits first, before I put water in

Hello,

we just had a liner installed after it was damaged in a storm. The installer cut the liner to fit the pool, there are cuts around the circular edge of the lower end of the pool, and the deep end it is cut 3 times. My previous liner was not cut, and watching videos I do not see anybody cutting the liner. Is this a normal practice, ever?

Hi Amy, no cutting of the liner to make it fit,just cutting out the drain, skimmer and returns, and lights, and steps, but never cutting the liner to make it fit the pool. Is he cutting and creating new heat welded seams on site? I’ve not heard of that before.

So now I can’t get the liner back in at the point where the shop vac was sucking air during the full. How can I correct this???

Hi Holly, yes I know what you mean, especially if you use a large 3 or 4″ shop vac hose, it can stretch the liner in that area. It is important to snap the liner back soon after the hose is removed, to prevent it sagging or being pulled down. If it has already been pulled down lower than the track, you may be able to heat it up (carefully) with a hair drier briefly (plug into GFCI outlet), and then use your brute finger strength to pull it up into the track. This works well if it’s less than an inch below the track. If it is stretched more than that, you risk tearing the vinyl, and so the cure would be to remove the water down to a level where you can pull it up, which may be most of the water 🙁 If it has not pulled down much, but you just have a bump of vinyl, what you do is sort of stuff it into the liner, and push the slack down the wall, lifting adjacent parts of the liner, to slide the bead down the track a few inches, on each side. Might take a couple of adjustments, sometimes, to get it to lay flat in the track.

So there is no glue or any adhesive. You just suck all the air out to set the liner?

That’s right, the liner is draped across the pool and locked in at the top track and adjusted somewhat. Then the liner vac is turned on (larger pools may need two vacs running), and all the air is sucked out from behind the liner, and it fits tightly like a glove. Then you affix the main drain ring and cover, and start filling the pool, leaving the vac running until the shallow end floor is covered

That’s right, the liner is draped across the pool and locked in at the top track and adjusted somewhat. Then the liner vacs are turned on (larger pools need two vacs running), and all the air is sucked out from behind the liner, and it fits tightly like a glove. Then you affix the main drain ring and cover, and start filling the pool, leaving the vac running until the shallow end floor is covered

[…] 5-Step Inground Pool Liner Installation […]