The pool pump is noisy, leaking, smoking or just plain not working. This could be urgent if the pump is at risk of stopping altogether. Without a pump to circulate the water, hot weather will turn it bad – quick.

If your pump is down, lower the pH to 7.2, and shock the pool. Brush and skim twice daily to try and keep it clean and circulated.

The pool pump is the workhorse of the equipment pad – pulling the water from the pool and pushing it through your filter and heater. And when the pool pump ain’t working – ain’t nothing working!

When we get orders for pool parts here at In The Swim, they are automatically triaged by our system to a priority status. That’s because pool pump parts can be very urgently needed.

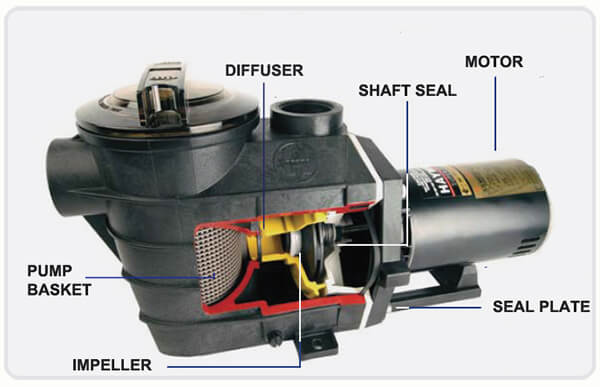

Understanding the parts of your pool pump is simple enough, and that is the goal of this blog post. Let’s start by breaking down the typical parts of a pool pump, with some typical problems and solutions.

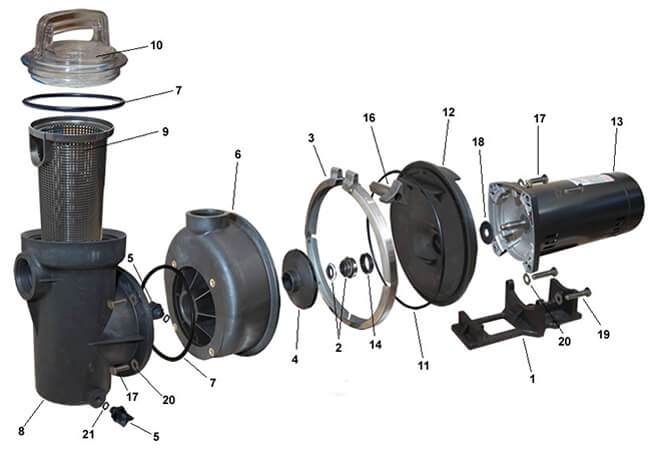

Hair & Lint Pot (8)

Also known as the strainer pot, the hair and lint pot has a pump basket (9) acting as a pre-filter for the pump, to strain out particles that would clog the impeller. The strainer pot must be air tight for the pump to work properly, and when it is, the pump basket is under a vacuum, so any small void in the works will suck in air, eventually causing the pump to lose prime. There are four areas that this could occur – where the pipe enters the hair & lint pot, and on the opposite side where the pot bolts (17) to the volute (6). Air can also leak from the o-ring (7) that fits around the pump lid (10), and through a loose drain plug (5), or one that is missing an o-ring (21). Water left inside a hair & lint pot during freezing weather will almost certainly crack the hair & lint pot.

Volute (6)

Also known as the impeller housing, the volute is designed to create pressure by diffusing the water as it is thrown out of the impeller (4) vanes. Some pool pumps also use a diffuser, (shown right) also known as an impeller shroud, which helps to increase pressure further on high head pumps. The volute also requires an air tight connection on all sides, to prevent air and water leaks. Air leaks on the front if the connection to the hair & lint pot is loose, and water leaks to the rear, if the connection to the seal plate (12) is loose, or if the drain plug on the bottom or the pipe carrying water out of the volute, is loose.

Seal Plate (12)

The seal plate makes a seal against the volute, with the assistance of the seal plate o-ring (11), and the clamp band (3), or sometimes with a set of nuts and bolts. Loosening the clamp knob (16) allows one to “crack the case”, or open up the pump to inspect the impeller (4), and remove the motor from the ‘wet end’ of the pump. The seal plate also holds the smaller half of the shaft seal (14), press-fit into the center of the seal plate. The motor bolts to the back of the seal plate with the motor shaft extending through the seal plate. The other half of the shaft seal (2) is installed onto the motor shaft, and the impeller threads onto the end of the shaft. The longer motor bolts (19) run through the motor support bracket (1).

Pump Motor (13)

The electric motor has a particular horsepower, voltage and service factor. It also has a particular flange type, either square or round on the shaft end. A slinger (18) comes with the motor, a small rubber gasket that rides on the shaft to sling away any water that makes it past the shaft seal. On the back cap of the motor is a 3/4″ hole that allows you to thread in a wire connector, to bring the wires into the motor. Also in the rear of the motor are parts such as the capacitor, a centrifugal switch and the terminal board, where the wires connect.

Pool Pump Troubleshooting Guide

- IF your pump is leaking AIR – look for the problem around the Hair & Lint Strainer.

- IF your pump is leaking WATER – look for the problem to be in the Volute or Seal Plate.

- IF your pump sounds like a SCREECH owl, the motor bearings are shot – rebuild or replace the motor.

- IF your pump sounds like it’s Gargling ROCKS, it is starved for water, look for obstructions or closed valves.

- IF your pump is overheating, check the motor air vents have adequate air flow, and voltage is correct +/- 10%.

- IF your pump is not pumping water, check for an air leak first, then inspect the impeller for damage or clogs.

Pump Problem or Motor Problem?

The electrical motor is the back half of the pump, connected to the front half of the pump (sometimes called the wet end) by a seal plate, which bolts or clamps the two pump halves together.

Motor problems could have symptoms of not starting, overheating, or a loud, screeching operation, which indicates that the shaft bearings have gone bad.

Pump Problems (wet end) includes all of the parts where the water moves through, such as the pump pot, pump basket, volute, impeller and diffuser; sealed up with several gaskets and o-rings, and a mechanical seal on the motor shaft.

Wet end problems include leaking – air or water, broken baskets, worn seals or o-rings, clogged impellers or diffusers, cracked volutes.

Once you determine the items that are causing the issue (call us if you need help), you can price out the pump parts needed, and determine if it makes sense to repair the pump, or replace the entire pump and motor.

REPAIR your Pump When:

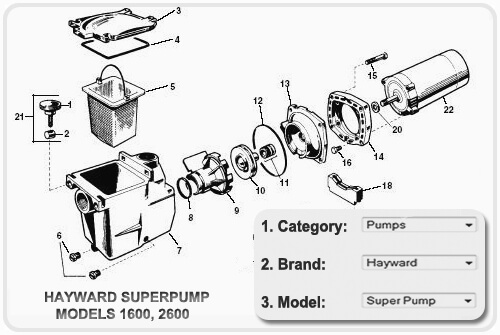

1. The cost of pump or motor repairs is less than the cost of a replacement pump. Determine the parts you need by pulling up your pump schematic in our Pool Parts section. Let us know if you need any assistance in identifying the correct pump parts.

2. Your motor (or pump) is less than 5 years old. Motors can last up to 10 years, so if you have lots of life left in the motor, repairing the pump may be wise.

3. You want to avoid any plumbing work involved in connecting the new pump.

4. You enjoy tinkering with your pool equipment, and solving simple mechanical or electrical problems.

REPLACE your Pump When:

1. You Live in Arizona, California, Florida, Nevada or Texas. If you have a standard motor over 1hp, and are located in one of these energy conserving states, the law requires most pools to install an energy efficient pool pump. Check the website of your state or local government for requirements, but it usually calls for either a dual speed or variable speed pool pump (or motor) be installed.

2. Your pump is undersized or oversized for the application. If the filter pressure is running 20-30 psi, your pool pump may be too large. Switching pumps to a lower flow model, or changing the pump or motor/impeller to a lower horsepower, can reduce pressure, improve flow, and reduce energy consumption.

Undersized pumps, although less common, could be having trouble keeping the pool clear, or may require nearly 24 hour operation to do so.

3. Your motor is older than 5 years, or has suffered fatal damage -and- there are other expensive parts that also need replacing.

4. You don’t enjoy tinkering with equipment, and would prefer to have a reliable new pump, with a new factory warranty.

How To Select a New Pool Pump?

The best match would be to replace with the same make and model pump you have now, unless you found it’s flow rate to be severely lacking, or you are required to install a variable speed pump.

When your pool was originally designed, we can assume that the designer did the math, adding up all of the flow resistance, measured in feet of head, and selected a pump and filter based on these computations. The plumbing portion of pump installation will usually be easier if you replace like with like, as the height and setback of the in and out ports of the pump will line up with your existing plumbing configuration.

If however, your old pump is no longer made, or not made in an energy efficient model, or the entire pump and filter system is being renovated, you can switch pump models or manufacturers without a problem. Most important in changing pump models is to use the flow charts to get as close as possible to the flow rate and pipe height and setback measurements of your existing pump.

Remember to match horsepower, pump type and flow rate. Use the Flow Rate Charts, (see sample chart below) based on a average feet of head (vertical axis) of 20 feet. This is the only true way to compare pump to pump flow rates. Since you probably don’t know the exact amount of resistance in your system, measured in feet of head, use an average amount, say 20 ft, when comparing your existing pumps flow capacity to a different make and model pool pump. (System resistance may be listed in original pool paperwork).

For Americans, it’s only natural to want the big V8 power plant, but a pump that is too powerful could actually prevent filtration while damaging the filter and heater. Pipes or plumbing fittings could even be blown apart. When matching pumps to filters, check the Design Flow Rate of the filter from the filter label. The average flow rate for the pump you select, should be within 10% of the filter’s Design Flow Rate.

Remember, this is an urgent decision! Pool pumps need to operate every day during the summer.

Thanks for the tip that 5 year is still pretty new when it comes to pool pumps. I’m currently planning to search for swimming pool pump repairs because mine suddenly stopped working the other day and it started emitting a scent that’s similar to burning plastic. I hope that once it’s been inspected, I wouldn’t find out that I’d need to get it replaced.

I replaced my pool pump 3 months ago.

Yesterday the pump is running, water is flowing through it, my filter pressure gauge stays at zero

I tried fishing the lines to the pool, found nothing

I pressurized with a bladder,the water flows out

Could it be a defective pump?

Hi Michael, could be a defective pressure gauge. It could be a clogged pump impeller, or pump basket. Could be an air leak before the pump, from a loose pipe coming in, or loose pump lid, or missing pump lid o-ring. Could be that the filter valve is allowing a lot of water to bypass the filter tank, but it is probably not a defective pump.

Thank you for pointing out that if the pool pump is leaking or smoking it could be urgent and you should get it fixed as soon as possible. My husband has noticed that our pump is doing both of these and now I am needing to find a repair service. Hopefully, I can find the best one in my area to get out pool up and running again.

I purchased my pump from your website 2 weeks ago. It’s super loud and is getting way too hot. It’s installed correctly and attached to the base correctly. What could be the issue? I’m super disappointed because I can’t exactly send it back and wait for over a week to get a new pump because the pool will be green.

Hi Wendy, a loud pump could be vibration, especially if installed on a wood deck, but not usually an issue on concrete. Second cause could be cavitation, or when a pump is installed that is ‘starved for water’, because of 1.5″ piping, just two pipes usually, when it would prefer three, or 2″ plumbing. This sound is different from vibration, and has been described as if the pump is gargling rocks, or a low pitch, grinding noise. A third cause of noisy pump is bad motor bearings, which have a higher pitched, metal to metal sound, can be heard by distant neighbors sometimes. In any case, if you disconnect the motor from the pump, and turn on the motor briefly, if it is quiet when removed from the pump, then it’s not the bearings, but either cavitation or vibration. As for temperature, all motors run too hot to touch, about 140-150°, if it gets too hot, they have a thermal overload that actually cuts the pump off, for about 20 minutes, then it will reset and turn back on.

Thank you. So if it is vibration (I don’t think it is because it’s on concrete) or cavitation what can be done? It’s def not a high pitched sound or like a rocky sound. More like a loud fan with a slight grinding.

Hi Wendy, it wouldn’t be a fan noise, although the motor does have a fan, that’s because at 3400 RPM, any misaligned fans or debris is quickly ground down to nothing, and then no noise. If you know that the pump is more powerful than the previous pump (and not all same horsepower pumps are equal – a 1.5 hp whisperflo produces twice the water flow as a 1.5hp superpump), increasing the above ground suction side plumbing to 2″ PVC can help, from the ground upto where it enters the pump, the only other option is very hard to think about – adding another skimmer or suction line from the pool.

So if I change the pvc from 1.5 to 2 from the skimmer to the pump would I be able to leave the rest at 1.5 or would I have to change all the pvc?

Hi Wendy, if you have access to the plumbing (ABG pool?) then yes, go ahead and replace the pipe size to 2″ from the skimmer to the pump, that may be enough to quiet the pump down. It’s primarily a suction-side problem, so you should not have to touch the return side, after the filter plumbing. Be sure to leave 12″ of straight pipe run in front of the pump (no valves), and try to reduce the number of bends in the pipe, 90’s and 45’s. Use sweep elbows where possible, rather than hard 90’s.

I have a one and a half HP pump to feed my diy solar heater. The pump sends the water up 16 feet via 2″ pipe then through the heater which is about 800 feet of 1/2″ hose. I am only getting a trickle of hot water back into my pool. I’ve read that every 10 feet of hose equals about 1 ft of head, so is my pump strong enough to do the job?

Hi Trevor, it should be strong enough, do you have a 3-way valve or some way to control the flow to the solar hose, and the flow that can bypass the solar hose? 800 ft of hose is a lot, and might be a lot of head if there was no bypass.

I have a Centry A O Smith B982 2 speed Whisper Free pool pump motor. (So it runs 24/7) It started making a higher pitch sound than normal. So I replaced both bearings. Once I put it back together I could turn the shaft very easy by hand. (Also put a new seal pump kit on it before completely putting it back together.). After hooking the power back up & turning the breaker back on it would just hum like it was binding. If I turn the back of the shaft to help it get stated it kicks of and runs. So I thought the capacitor was bad & replaced it. Same thing, still have to turn the shaft at the back of the motor to get it to run. So then I replaced the impeller thinking that might be it. Still the same way. So I took the front pump off of the motor & turned the breaker back on with nothing attached to the pump & it still hums until I spin the shaft to get it started.

Any ideas what it might be? Oh when it does run it’s not as quite as it use to be but quieter than it was before I replaced the bearings.

Hi Wendell, check the start switch and the centrifugal switch in the back of the motor, located at 6 o’clock and dead center, respectively. The copper tabs may have too much tension, or not enough, there is a screw at the bottom. When the centrifugal switch opens, the two copper tabs should separate. Also check that the seal half (the spring half) was installed properly, with soft side facing impeller, and hard plastic side facing motor. Also check for loose wires…? Your assumptions have been correct so far, it’s usually either the capacitor or the motor is binding, when the motor ‘hums’. And your last sentence, not very quiet – hmm, not sure but wondering if the bearings are seated fully – but not sure. If you have a local electric motor shop, they might charge only $25 or so to bench test the motor…

Went to turn pump on to start up pool and the pump just made a sound and nothing . The pump is 9 years old. My husband was going to get a new pump but was talked into trying to take it to a local motor repair shop. What do you think? The motor hummed for about thirty seconds and shut off?

Well, the motor shop idea is sound. They can rebuild the motor, or if it’s dead, they can replace it with new, at about 1/2 to 2/3 the cost of a new pump. Might just need a new capacitor, but it may be best to get a new motor, they only last 7-9 years in most cases.

my pump that is 2 years old started smoking and when I re-attempted, it still smoked but less and then turned off. I had an electrician install and pump worked fine last season. I had water in the basket and pressure. Any ideas that I can look at before thinking I need to replace the pump.

A smoking motor is never a good sign, something burned up. look in the back to see if it might be the capacitor (left side, 9 oclock) that ruptured and can be replaced easily or if you can see burn marks near the terminal board, caused by wires touching or loose wires.

what are the signs of a weak electric motor? poor water volume?

Hi John, actually motors don’t get weak, they either work or they don’t. Well, actually a sign of a weak motor could be slow starting, but that may be a capacitor problem, not really a motor problem. If your flow rate is lower than normal, it’s not a weak motor, but could be: 1. clogged impeller, 2. clogged pipe or valve, 3. closed or partially closed valves, 4. dirty pool filter or pump basket (or skimer baskets), 5. Air leak in front of pump, 6. collapsed flexible PVC pipe on the skimmer or drain lines.