When is a pool filter not a pool filter? When water is bypassing your filter, and returning to the pool unfiltered. It’s a more common problem than you may think. If your pool water is hazy, cloudy or dull – or if you are plagued by frequent algae blooms, you may have such pool filter problems.

Pool water problems could be related to water balance, or lack of consistent sanitizers. It could also be a pool filter that is undersized, or one which needs new filter media (sand, cartridge). Poor water can also occur from a clogged pool pump, or one that is taking on air or losing prime.

In this blog post however, we take a close look at how to check your filter – to make sure that it’s not sending water back to the pool unfiltered.

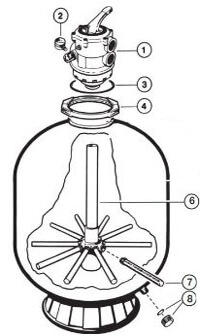

SAND POOL FILTER PROBLEMS

Filters that are too small for an overpowered pump can begin to channel. If the water can find a faster way, around the sand, or bypassing the sand – it will take an easier route, to avoid being pushed through the sand bed.

Filter sand that has hardened, or calcified, due to extremely hard water or high levels of TDS can develop channels, where the water pushes itself around what has essentially become chunks of sandstone. Not very common.

Another problem inside the sand filter can occur if the standpipe (#6) becomes cracked or breaks open. If the standpipe (or the laterals (#7) at the bottom of the tank) become cracked under the sand level, you will also notice sand coming into the pool.

If the crack is above the sand level, or if the top of the standpipe is not pushed all the way into the top mounted multiport valve, water can be pushed into the standpipe, or into the multiport (#1), without having gone through the sand bed. Poor filtering is the result.

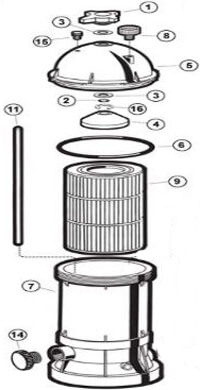

CARTRIDGE POOL FILTER PROBLEMS

Cartridge filters have their own unique problems that can allow water to bypass the filter cartridge. Instead of flowing through the cartridge (#9), and being forced through the pleated material, water can sometimes find a fast route back to the return line.

Cartridges that are cracked on the ends, or obviously collapsed should be replaced, as they may not seat properly on the top and the bottom. The seal is very important to prevent water from slipping by the heavy rubber ends.

Water can bypass most directly through the cartridge. If you notice holes in between the pleats, it’s time for a new cartridge. If the horizontal bands holding the cartridge pleats together are broken, replacement may not be too far away.

Also at issue are the many parts used in some cartridge pool filters. In this particular example, the Hayward Star Clear – if one of those little washers (# 2 or 3) or the E-clip, (#16) or the cone (#4) end up missing, is cracked or misaligned, it could allow the filter to come out of position. and water can get around the filter cartridge.

With any cartridge pool filter, make sure all parts are in place and that the cartridge is fully seated into the open ends, top and bottom.

DE POOL FILTER PROBLEMS

DE pool filters also can allow water to bypass the filter medium, or the DE filter grids, in this case. The grids hold the cake of DE powder which does the filtering, and this powder will usually alert the alert DE pool filter owner that something is wrong.

Usually, a breach of the DE grid assembly will make itself known by spewing DE powder into the pool. You may notice a large cloud of it coming into the pool after backwashing and recharging. Or, you may notice a light brown, sandy dust laying on the pool floor. Oftentimes, the DE loss is not continuous, and you may not even notice that your filter is bypassing a % of water.

In the DE filter style shown left, the manifold (#1) on the top is a common cause of a bypassing DE filter. You may have a missing or broken air bleeder hose (#2), sock or screen. The manifold itself may have cracks, usually a result of the assembly falling over on the concrete.

If the grids themselves are not fully inserted into the manifold, and if the assembly itself is not altogether tight, water can make its way past the grids in the small spaces up top, between the manifold and the grid. Having all grids properly spaced and aligned, with tight through bolt(s) – so that the assembly is as tight as possible, is the right way to reinstall the grids after cleaning.

There is an o-ring on the top of the standpipe, to seal the manifold and the standpipe (#3). This could allow a small quantity of water to sneak by the grids. Rips or tears in the fabric of the grids, or breaks in the pvc standpipe can also send water back to the pool, unfiltered.

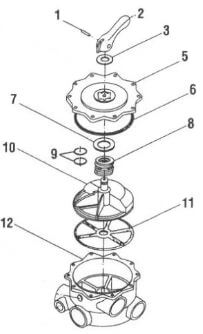

MULTIPORT VALVE PROBLEMS

Could be that the problem is not the filter at all, but the filter valve. The most common type of filter backwash valve used on sand and DE pool filter is the Multiport valve. Cartridge filters are not backwashed, but are hosed clean manually, so there is no multiport or push pull valve used on cartridge filters.

The Spider gasket (#11) can pop out of the groove (#12), and allow a good bit of flow to escape filtration. If the spring (#8) cracks, the rotor (#10) can raise up and allow quite a lot of flow rate to slip by. A broken spring will make itself known by a floppy handle, and you may also be unable to turn the valve

Oftentimes, a bypassing multiport valve will also have the simultaneous problem of a leaking backwash line, which can be immediately concerning. Shut off the pump and reposition the handle, to make a better seal, and turn the pump on again.

If your multiport valve continues to leak out of the waste line, it could be leaking into the return port as well. Open it up and inspect all the parts, if there is a problem, you should be able to see it.

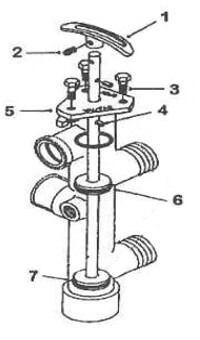

PUSH PULL VALVE PROBLEMS

Push-Pull valves, aka Slide Valves, are a simple two position valve. Filter, and Backwash are the two options, and depending on which position the plunger is in (up or down), the water will exit the filter tank to the return line, or to the backwash line.

When the plunger is pulled up, or pushed down, it moves two disks (#6 and 7) attached to the rod. These two disks are wrapped in a thick o-ring (one that you should be lubing regularly). The o-ring seals up the piston against the walls of the chamber and keeps the water going in a forced direction.

The push-pull will allow water to bypass a sand or DE filter if the top disk or o-ring (#6) is missing or worn. If the bottom disk or o-ring (#7) is the problem, your bypass will be leaking out of the waste line.

Having your pool filter at 100% can be important when trying to clear up a poor water situation or when trying to figure out why the pool isn’t clearing up and the filter isn’t building any pressure. Take a look to see that you’re not sending a % of your water back to the pool, unfiltered.