In the pool world, there are several different types of motors used on pool pumps. Knowing the correct motor type is important if you wanted to repair or replace a failing or troublesome pool motor.

Pool motors bolt onto the pump seal plate or volute, also called the “Wet End” of the pump, via four bolts. The motor, or the back half of a pool pump is not often called the “Dry End” of a pool pump, but could be termed as such, as the shaft seal serves to prevent leakage along the shaft, keeping the motor dry.

Let’s take a look at pool pump motor and flange types.

Pool Motor Types

1. Variable Speed Motors

These motors are the new kids on the block, and they are completely different than regular motors, not only in function but also design. They are designed to operate a several different speeds (variable speeds), to reduce energy usage and for performing different tasks (filter, cleaner, fountain). VS pool motors are TEFC (Totally Enclosed Fan Cooled) and the permanent magnet motor is an ECM (Electronically Commutated Motor).

2. Capacitor Start – Capacitor Run

This type of pool pump motor has the large hump on the top, housing a large run capacitor, (the silver type) which acts as a battery to assist in running the pump motor. This design increases efficiency, or reduces amp draw. A secondary capacitor is used in the rear of the motor to assist with starting of the motor, to reduce the energy required to bring the motor up to full speed (3450 rpm).

3. Permanent Split Capacitor

This design, commonly used on Century motors, is often referred to as a switchless motor, because it doesn’t have the typical centrifugal switch threaded onto the rear of the motor shaft. The PSC motor uses a top mounted run capacitor for run operations, but is permanently wired to the power source. The design has less starting torque and uses more energy than a capacitor start design.

4. Capacitor Start

This is a very common inground pool pump motor type, used on many pool pumps. Housing a start capacitor (the black cylinder type) in the rear of the motor, the starting torque is higher, and the starting current is lower than other motor types of the same size. When the motor reaches about 2500 rpm, the start winding and capacitor is switched out of the circuit.

5. Split Phase

Also called a split phase induction motor, this design has a start switch and a start winding, but no capacitor. Once the motor reaches near design operating speed, the centrifugal switch opens, disconnecting the startup winding from the power source. The motor then operates solely on the main winding. This type of motor, shown with the 48 Frame, is used for spa motors and aboveground pump motors.

Pool Motor Frame Types

1. THRU-BOLT – 48 Frame

Also known as 48 Frame, Thru-Bolt motors are used on hot tubs, jetted tubs and aboveground pool pumps. They are distinguished by the built-in pedestal or feet on the bottom of the motor, in addition to their diminutive size. This motor gets it’s name from the four bolts that run through (thru) the motor, from front to back.

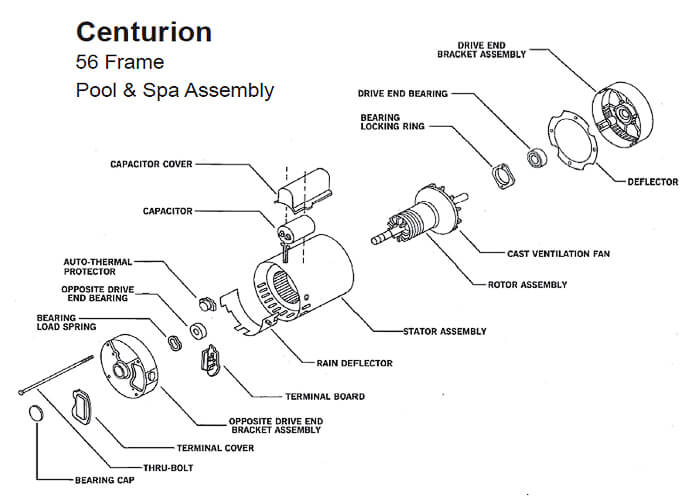

2. C-FLANGE – 56 Frame

Also known as the 56 Frame, the C-Face, or C-Flange motor gets it’s name from the circular face or flange that meets up with the pool pump. 4 short bolts secure the motor to the pump, pushed in through the tabs or ears around the face of the motor. The 56 Frame is available in two types, the more common 56J with a threaded shaft used on most Hayward and Jacuzzi inground pool pumps, and 56C with a keyed shaft, used on older brass pumps by Sta-Rite and Purex.

3. SQUARE FLANGE – 48Y/56Y Frame

Also known as the 48Y or 56Y frame, this motor is possibly the most common flange type (or frame type) used on swimming pool pumps. It gets it’s name from the square shape of the flange that bolts onto the pump wet end with the use of 4 short bolts. The 48Y square flange motor has a threaded shaft for the impeller to thread on, and is used on all inground pool pumps made by Jandy and Pentair.

How do Pool Pump Motors Work?

The electric motors used on swimming pool pumps operate in the same way as other electric motors around the home. In most cases, pool motors are started with the assistance of a capacitor, until the rotor (or armature) reaches sufficient speed to continue spinning the rotor itself, by the use of magnets. Oppositely charged magnets on the rotor and on the stator, attract and repel each other, which keeps the rotor spinning, at an amazingly fast speed of 3450 RPM! The rotor is balanced inside the stator, with the use of sealed bearings on each end of the shaft, pressed into each end bracket. In the case of a pool pump, one end of the shaft is connected to a curved vane impeller, housed inside of a volute, to create suction, lift and pressure.

Pool Pump Motors & Parts

In case you have a need for replacement pool motors, or need motor parts like bearings or capacitors or shaft seals – visit our pool pump Motors & Motor Parts page.