Spring is here and summer is right around the corner. For those in the snowbelt who close down their pools, their equipment has been laying dormant and needs to be put together and restarted. This is often a time when you might encounter a problem at the equipment pad. We will discuss the top five issues that arise concerning your pool pump, which is the heart of the filtration system. These top five are also applicable to pools that run year-round.

1. Pool pump will not start. There are several possible explanations as to why your pool pump will not start. Remember the adage, “The problem lies where the power dies.” First, ensure power is making it to the pump. Check all breakers from inside the house to any subpanel the equipment is receiving power from. Check all time clocks and automated controls to ensure correct settings. You can even listen to hear if you are tripping a breaker as you turn on power or if the motor is humming. If you are comfortable using an electric test meter you can access the terminals by removing end cap of motor. At that time ensure the circuit boards and wiring are in good condition. Once confirmed that power is being delivered to the motor we can deduce the issue lies internally with the pump. The motor could be seized, the capacitor bad, or a wire in the rear of the motor could be disconnected or otherwise shorted.

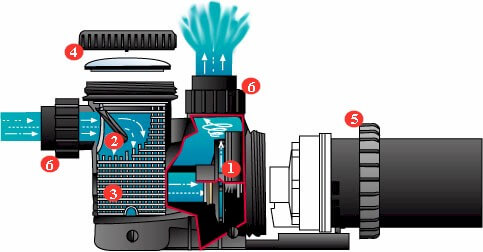

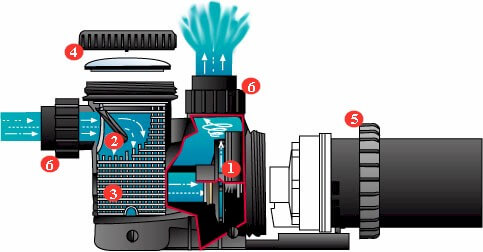

Usually, the issue is a bad capacitor. If the shaft on the motor spins freely, we can assume that the capacitor is not storing enough energy to start the pump. If the shaft does not spin, the motor is seized internally or is being restricted by a pump component. You can pull the motor from the pump to see if this frees up the shaft. If it does, the issue lies within the pump housing. Check for warping or deformed or cracked impeller, diffuser or volute. Capacitors are essentially batteries to jump-start the motor quickly up to 3450 rpm. You can

test a capacitor with an ohm meter to determine their stored capacity.

If the motor is removed from the pump and is receiving power but not turning over, the pump motor may be seized. Bearings and windings can seize and rust, especially during long periods of inactivity. A seized motor will try to start, making a humming or buzzing sound, and eventually, usually, trip the breaker. The solution is to get a wrench on the back of the shaft, under the centrifugal switch, and repeatedly move the shaft back and forth to break the rust bond. It sometimes takes 5-10 minutes to free it up. If it still won’t start with the shaft turning freely, and the capacitor is good, then you may have shorting across internal windings, which usually means a new pool pump motor is in order.

2. Pump Will Not Stay Primed Once again it is a game of deduction. First, start at poolside. Ensure air is not being drawn in through a skimmer. Check that the pool water level is appropriate and no vortex is being created. Sometimes skimmer weirs get stuck in an up position, blocking the entrance to the skimmer. Next, check the suction pipes/valves and pool pump. Make sure valve lids are all tight, and pump drain plugs have the proper O-ring or Teflon tape. Hose clamps that connect any poly piping should be retightened. Another common place is right at the pump lid. Ensure all pump lid O-rings and gaskets are in good condition and are not dry rotted.

Check the intake port on the pump, another area that is prone to vibration and heat that makes it yet another candidate to be a place air can get in. Use all your senses to locate any bad connection. Listen for the hissing of air sucking in or spraying of water out as you start and stop the pump. You may need to put some pressure on it! Using a drain king can be useful to pressurize the line from the skimmer up to the pump or filter. This is done with the pump off and a plug is placed inside the pump, or you can close the multiport valve or close a return line valve to isolate everything from the skimmer up to the point where you close it. Under pressure any leak or void in the suction side of your circulation system will result in dripping water (whereas under a vacuum it draws air in). Other components may have experienced freeze damage or warping. Inspect for pinholes, hair line cracks, or misshapen mechanisms.

3. Pump is leaking. Often a pump will leak or spray water affluent to the intake after the water has become pressurized. Usually this can be explained by cracked or deformed components, O-rings, or a bad mechanical shaft seal. When water is pouring out behind the seal plate where the shaft enters the housing it indicates a worn mechanical shaft seal in need of replacement. A common leak on a pool pump is the connection on the return side. Such leaks on the effluent side (outflow) of the pump are usually caused by a schedule 40 pvc pool fitting shrinking. Using a schedule 80 or CPVC fitting will prevent this. Unions may need to have new O-rings, if you find that they are leaking.

4. Pump not moving water. The pump is fully primed and there are no air leaks. The pump strainer either slowly fills with air or does not show sign of water movement at all. Well, there are two possible explanations. One is that the pump is cavitating or starved for water. There is either an obstruction in the suction line or the line is collapsed. Collapsed lines need to be replumbed and are usually associated with poly piping or flex line. If you suspect there might be an obstruction you may need to put pressure on a line and attempt to unclog. You can achieve this using a drain king or pressurized air. More commonly it may be an issue with the impeller. Either the impellor is clogged or is broken. Address either situation and rectify the cause. A shattered pump basket would also cause this issue, with pieces lodging themselves in the impeller.

5. Pump costs too much to run. A high energy bill may mean your pump motor is drawing an excessive amount of power. The pump design may be causing this excess workload, which leads to a higher amp draw and will be reflected on your bill. Motor and pump design has improved over the years and your pump may be outdated and due for an upgrade to a more energy efficient pump. Make sure you are running the pump the time required to keep water clean and not running in excess. A timing mechanism should be utilized to avoid running your pool manually or 24/7. Pump design and efficiency are among pool product manufacturer’s top priorities. When your pump has seen better days you have several options to increase efficiency and lower your bill. Design has improved across the board.

Variable speed pumps are the hot topic today as they consume only the energy needed to complete the task at hand and utilize state-of-the-art internal components.

Spring is here and summer is right around the corner. For those in the snowbelt who close down their pools, their equipment has been laying dormant and needs to be put together and restarted. This is often a time when you might encounter a problem at the equipment pad. We will discuss the top five issues that arise concerning your pool pump, which is the heart of the filtration system. These top five are also applicable to pools that run year-round.

Spring is here and summer is right around the corner. For those in the snowbelt who close down their pools, their equipment has been laying dormant and needs to be put together and restarted. This is often a time when you might encounter a problem at the equipment pad. We will discuss the top five issues that arise concerning your pool pump, which is the heart of the filtration system. These top five are also applicable to pools that run year-round.